Halar® (ECTFE – Ethylene Chlorotrifluoroethylene) coating is a high-performance, semi-crystalline fluoropolymer. Known for its exceptional chemical resistance, electrical insulation, and low permeability, Halar® coatings are ideal for applications in extreme environments, such as the pharmaceutical, chemical processing, and semiconductor industries.

Resists a wide range of harsh chemicals.

Protects against corrosion in aggressive environments.

Withstands extreme temperatures without degradation.

Minimizes gas and liquid penetration.

Provides strong mechanical properties and durability.

Resists UV radiation and harsh weather conditions.

Acts as an effective electrical insulator

Prevents substances from sticking to surfaces.

60°C to 150°C (-76°F to 300°F)

230°C (446°F)

0.25 mm – 1.5 mm

up to 3 mm (on request)

| Property | Value |

|---|---|

| Density | 1.68 g/cm³ |

| Hardness (Shore D) | 75 |

| Melting Point | 230°C (446°F) |

| Thermal Conductivity | 0.22 W/mK |

| Dielectric Strength | 16.6 kV/mm |

| Tensile Strength | 45 MPa |

| Flexural Modulus | 1700 MPa |

| Water Absorption | < 0.01% |

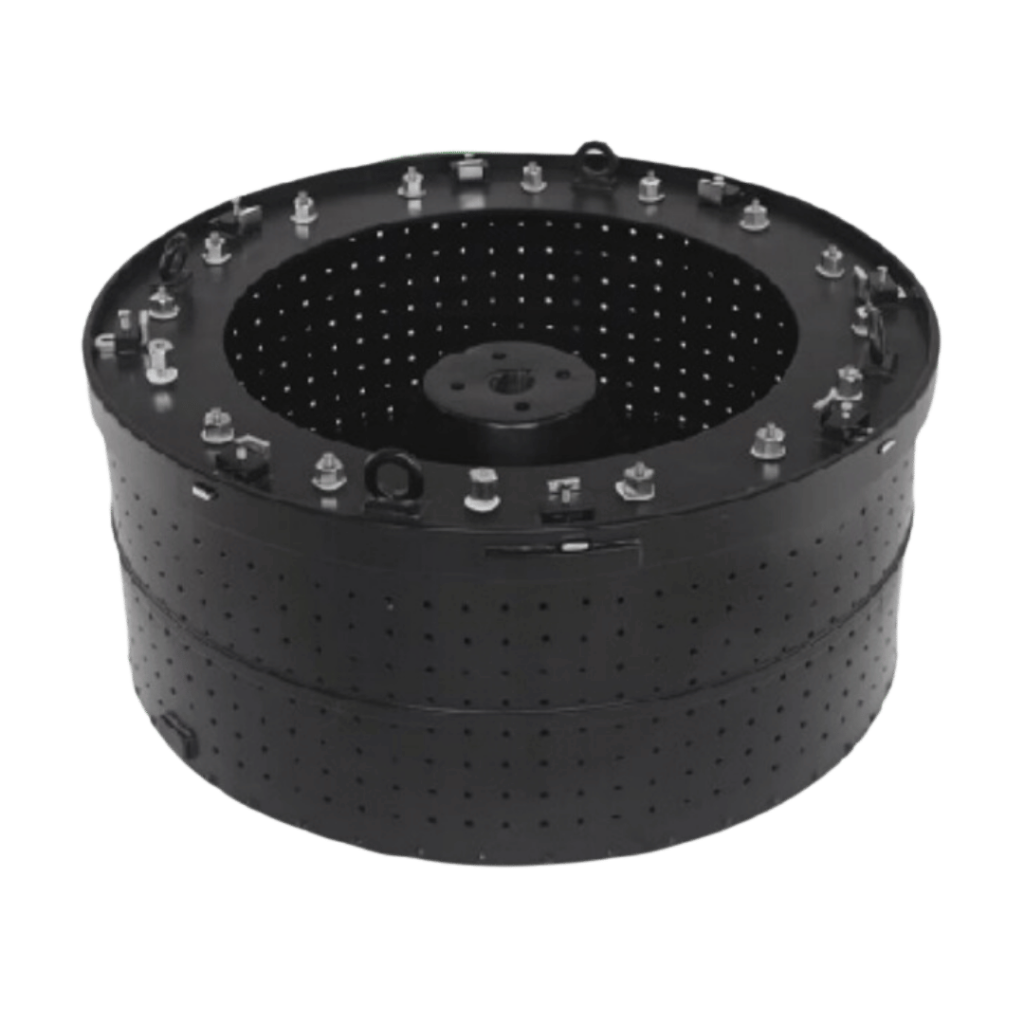

ECTFE coatings are widely applied in various industries for their superior protection. They are essential for lining tanks, pipes, and equipment in chemical processing plants, ensuring durability and resistance to harsh chemicals. In pharmaceutical manufacturing, ECTFE coatings provide contamination-free surfaces for equipment, maintaining the purity and safety of products. These coatings are also crucial in the food processing industry, offering protective, non-stick surfaces. Additionally, in semiconductor manufacturing, ECTFE’s purity and resistance to contamination make it the material of choice for safeguarding sensitive equipment.

Plot No: D-50, Phase-IV Extension. I.D.A., Jeedimetla, Hyderabad-500055. Telangana