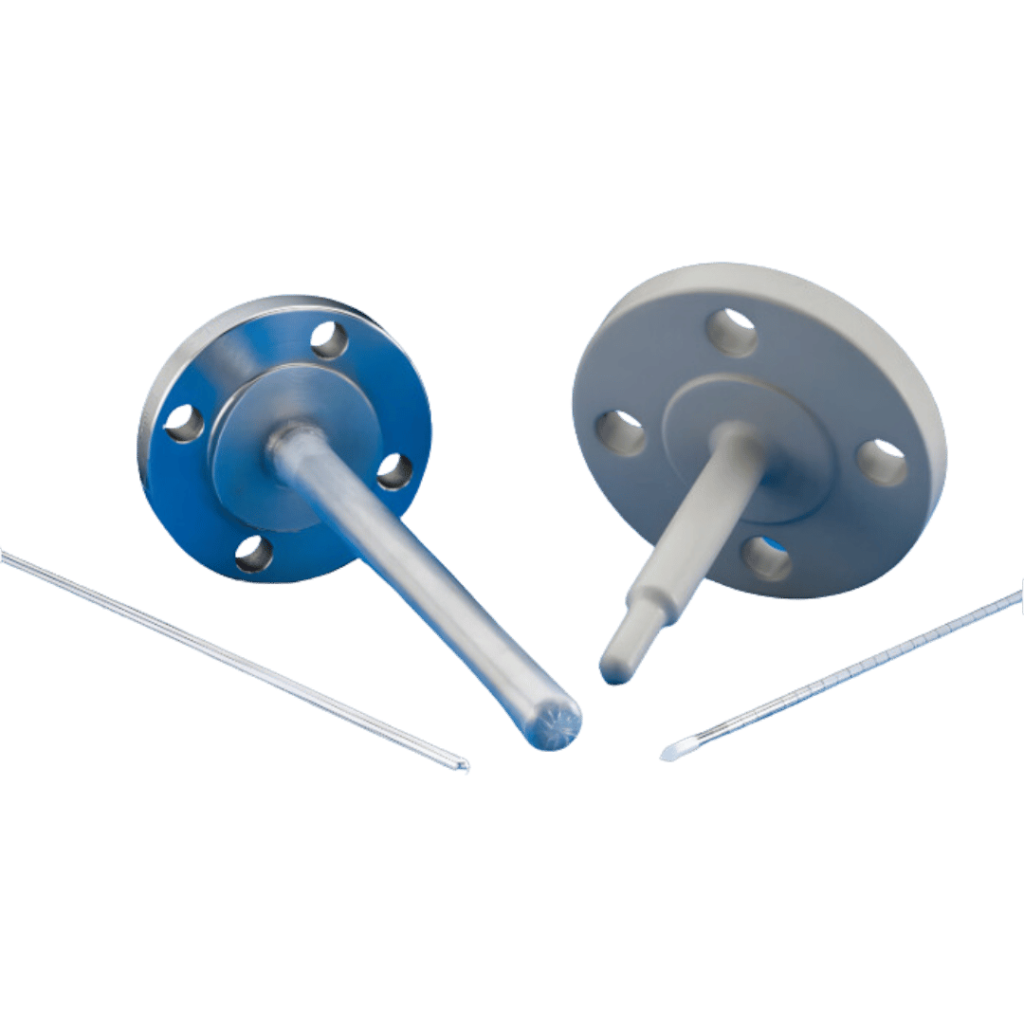

FEP (Fluorinated Ethylene Propylene) is a unique fluoropolymer coating, known for its superior chemical resistance, excellent electrical properties, and non-stick surface. FEP coatings are particularly valuable in industries requiring non-reactive, low-friction surfaces, such as pharmaceuticals, food processing, and chemical processing.

Offers excellent resistance to a wide range of chemicals.

Maintains performance under high temperatures.

Ensures a low-friction surface, reducing wear and improving performance.

Provides a smooth, non-stick surface for various applications.

Features a transparent appearance, allowing for visual inspection.

40°F to 302°F (-40°C to 150°C)

175°C (347°F)

0.2 mm – 1.5 mm

up to 2 mm (available on request)

| Property | Value |

|---|---|

| Density | 1.78 g/cm³ |

| Hardness (Shore D) | 75 |

| Melting Point | 175°C (347°F) |

| Thermal Conductivity | 0.19 W/mK |

| Dielectric Strength | 18 kV/mm |

| Tensile Strength | 50 MPa |

| Flexural Modulus | 1500 MPa |

| Water Absorption | < 0.03% |

FEP coatings are extensively utilized in industries where non-stick properties and chemical resistance are essential. They are commonly applied for lining tanks and containers, coating process equipment in the chemical, pharmaceutical, and food sectors, and insulating electrical components.

Plot No: D-50, Phase-IV Extension. I.D.A., Jeedimetla, Hyderabad-500055. Telangana