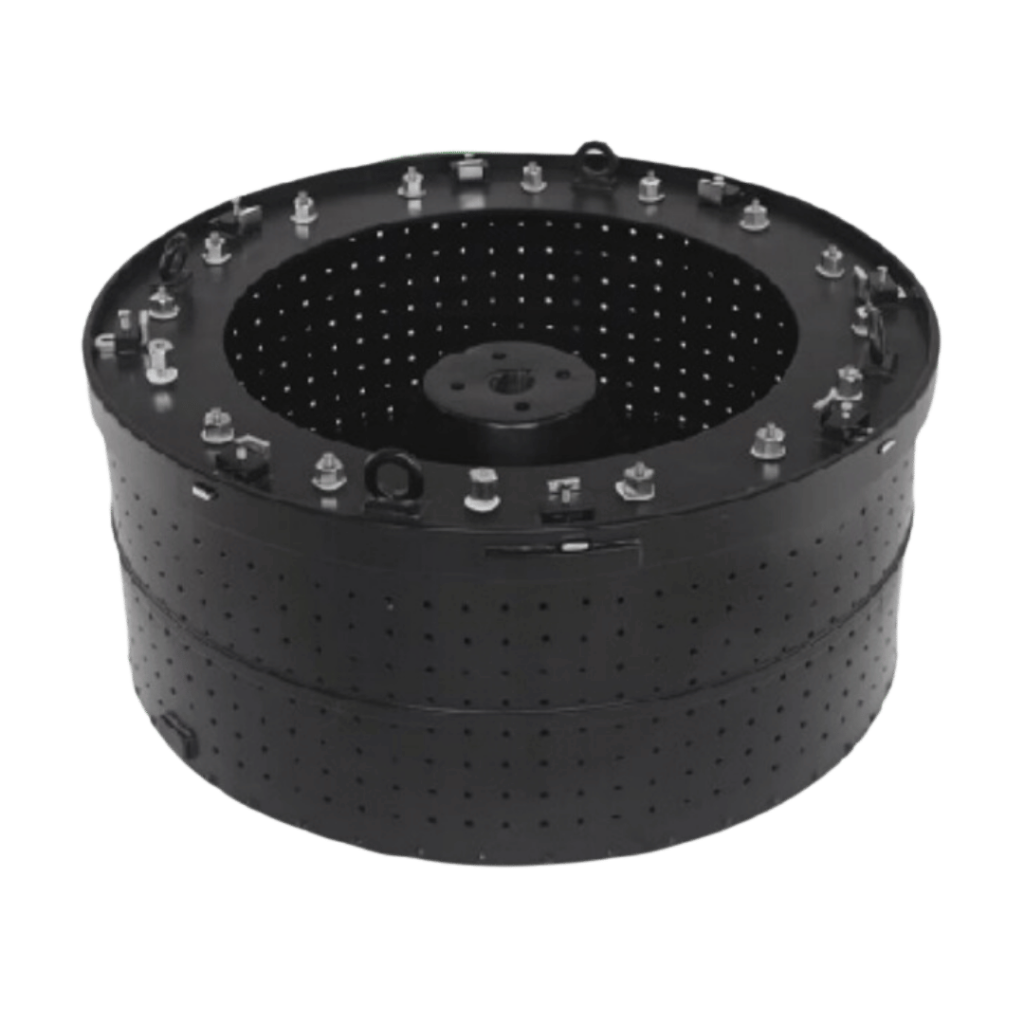

ECTFE coatings are widely applied in various industries for their superior protection. They are essential for lining tanks, pipes, and equipment in chemical processing plants, ensuring durability and resistance to harsh chemicals. In pharmaceutical manufacturing, ECTFE coatings provide contamination-free surfaces for equipment, maintaining the purity and safety of products. These coatings are also crucial in the food processing industry, offering protective, non-stick surfaces. Additionally, in semiconductor manufacturing, ECTFE’s purity and resistance to contamination make it the material of choice for safeguarding sensitive equipment.